Viskocil

The older generation of watchmakers, not only in Germany but also throughout the world, faced a big disadvantage in their professional lives compared to the young watchmakers of today. Watch experts who are approaching retirement today had to deal with quartz watches after having been trained to make and repair mechanical wristwatches, grandfather clocks and/or pocket watches. No young trainee, male or female, who started his or her apprenticeship in, let’s say the mid 1960’s, intended to work on battery powered electronic devices showing the time. During this period, watchmakers had to deal with products whose only similarity to traditional watches or clocks were their dials, hands and cases.

Today, the situation looks totally different. Watchmakers are a rare species and the ones who still work in the industry are very much in demand and are paid high wages for assembling and repairing mechanical watches. A new generation of German watchmakers is emerging, along with those who weathered the storm of the quartz era, and both seem to be finding their niche in this growing industry.

One watch brand

Do you think it is possible for a watch company to survive by producing and selling only one model? Volker Viskocil, one of these young watchmakers, has proven that it actually is. Viskocil, who was born in 1964, lives and runs his watchmaker’s workshop in Nettetal, a town of some 42,000 inhabitants, located on the left bank of the Rhine river near the border with the Netherlands and the Dutch town of Venlo. Certainly not an area with a great tradition in watchmaking, but this doesn’t bother Viskocil, whose dream has been to build his own watches ever since he was a schoolboy. However, when he left school he decided to study construction at university. After he had finished his studies, he worked as a toolmaker but never forgot his passion for timepieces.

Following his dream, he decided to quit a steady, well-paid job a couple of years ago and start making his own watches. “It is important to mix tradition and one’s own thinking to be original,” he says. “Both are important and have to be in harmony with each other because tradition alone only causes imitations and works that only have their roots in the present are often missing a soul.”

Viskocil has succeeded in creating the right mixture and the construction of his watch was so unusual that the toolmaker turned watchmaker was allowed to become a member of the AHCI,

an exclusive international association of independent creative watchmakers.

Today Volker Viskocil whose brand’s logo is the ‘Double V’ is very successful with his wristwatch ‘V-30/45-01-A’ (‘V’ for Viskocil, ‘30’ for the movement’s diameter in mm, ‘45’ for the movement’s height in 1/10 mm, ‘01’ for the current revision status and ‘A’ for the indications).

The Viskocil watch, or ‘VA’ as it is often called, has some hidden features: The delta or ‘V’ shaped power reserve indicator also shows the letters ‘H’, ‘M’ and ‘S’ and is bi-functional. Every indi-cation of the watch can be set separately. When pulling and using the crown, the hand will jump to the particular letter that lets the user know which indication is being corrected. The hour hand can be set separately (useful for travellers and time changes in spring and autumn), as well as the minute hand, which jumps to a minute marker automatically as soon as the time is set by the crown. The power reserve indicator hand, pointing on the figure ‘S’, means that the seconds stop when setting the watch. The VA runs for 40 hours after it has been fully wound. When this time is over, a seconds stop device, connected with the power reserve mechanism, stops the balance wheel.

There are some more very innovative functions to be found hidden in the Viskocil watch. It seems that this young man with a passion for tradition is well on the road to success.

Double exclusivity

A very unexpected professional success has been achieved by Wilhelm Rieber who owns a small company named ‘Alt-Uhrmacherei’ in the idyllic village of Albstadt in Southern Germany. ‘Alt-Uhrmacherei’ means ‘traditional watch and clock making’. Until a few years ago, Rieber was mainly working on repairing valuable antique pocket watches, miniature clocks and wall clocks. His passion, however, has always been the craftsman’s manufacturing of fine timepieces, which he does alongside his repair work.

Already in 1984, at the age of 26, the young watchmaker started making his first watch with the legendary tourbillon mechanism. “I did it for myself,” explains Rieber. “I always thought, if I could only make my own watches.”

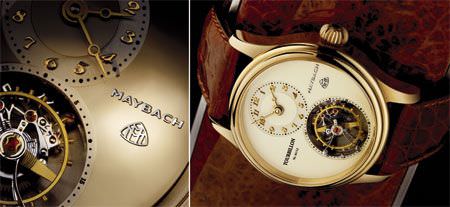

Rieber’s dream became a reality some four years ago, when he came in contact with ‘Maybach’, a car brand of Daimler-Benz which makes high-end, luxury automobiles. At the time, the head of Maybach’s marketing and communication department was looking for suitable luxury accessories for the Maybach buyers, who have to spend at least 365.000 Euros for one of the handmade limousines. The Maybach manager came in contact with the watchmaker from the Swabian Alps through a jeweller who had recommended him as someone with special skills. The car salesman was immediately convinced that Rieber’s tourbillon watch fitted the luxury cars perfectly. A flying tourbillon, with a diameter of 14.8 mm, the biggest one on the market and made by hand (except for the case, the dial and the hands) and individually equipped to the customer’s taste with diamonds and a handmade Maybach logo on the dial. It really is the perfect accessory for an automobile with a 12 cylinder engine, TV, fax, refrigerator, Internet access and special massage reclining seats with internal ventilation.

On 23rd April 2004, Wilhelm Rieber presented his first Maybach watch before an audience of 70 VIPs at a special event held by the car company. The timepiece was a flying tourbillon, available in a choice of yellow gold, white gold or platinum at a starting price of 120,000 Euros. The manufacturing of these exclusive watches is strictly limited to 12 pieces, according to the 12 cylinders of the car. The warranty lasts for twelve hundred days. Each timepiece takes Wilhelm Rieber six months to complete. So, in the near future, he will be able to build his own watches, earn good money and see his dream come true.

Maybach

Nautical instruments

Nautische Instrumente Mühle-Glashütte is one of many industrial watch production companies, but the story of this company led by Hans-Jürgen and his son Thilo is worth telling.

Hans-Jürgen Mühle has a great deal to say about being self-employed with a small company in the former GDR (Eastern Germany) and how he was a victim of a communist regime’s fight against privately structured economy.

After the German reunification in 1989, however, the small business, which was founded by Hans-Jürgen Mühle’s great-grandfather in 1869 and had produced mainly nautical instruments, successfully started making wristwatches. Little by little, the family business turned into a small industrial watch producer. Today Mühle’s 34 employees make a wide range of different watches, including special pieces for the crews of Germany’s SAR search and rescue squadrons helping ships and boats in danger in the North and Baltic Seas. Another product line consists of models under the name of Lufthansa.

The latest watch presented by Mühle has a nautical feel. The ‘Laser’ is named after a small, very sporty Olympic class sailboat. It highlights the important 15-minute period of time before the start of a sailing regatta. The first 15 minute section on the dials of these automatic watches is lacquered in a different colour.

Hans-Jürgen and Thilo Mühle

Mühle-Glashütte

Benzinger

The art of decorating

A completely different approach to watch manufacturing can be seen in the work of 45 year old Jochen Benzinger, owner of an engraver’s workshop in Pforzheim. Benzinger decorates a wide range of daily use items like pens and jewellery pieces. What is especially worth mentioning is that Benzinger decorates dials by hand engraving or with engine-turned patterns (guilloché).

In 1985 Benzinger took over an engine turning workshop, which had been in business for over five successful generations. This craft, originally going back to wood turning, became popular through Fabergé, the appointed jeweller to the Russian Czar. He used this technique as a base for his enamel items, today best known because of the famous Fabergé eggs.

Thanks to the renaissance of mechanical watches some high quality manufacturers currently use hand engine-turned dials for their products to give them an elegant and classic appearance. No wonder Benzinger’s customer list reads like a ‘Who’s Who’ file of brand names from all the Swiss and German watch industry.

Jochen Benzigern is only able to do this very specialised work because he started buying old turning engines in times when they either went to museums or were thrown away.

In 2002, Benzinger also started to produce his own wristwatches, featuring his original trade of hand engraving. This is mainly done on skeleton movements which he works on himself.

Curious about the future

These short and very different stories of people passionately working on mechanical watches at the beginning of the 21st century makes one curious about what the future has in store. There is no chance the German watch industry, once the second largest in the world, will be that big again, but people like Mühle, Viskocil, Rieber and Benzinger give a good reason to trust in the future successes of the German watch industry.

Source: Europa Star August-September 2006 Magazine Issue