n 2014, some of the biggest leather strap specialists in the watch industry came together to form a Swiss non-profit, the Assurance Qualité des Fabricants de Bracelets Cuir (AQC). The five founding members – Brasport and Multicuirs in Switzerland, Camille Fournet and Interstrap from France, and Austrian manufacturer Hirsch – represent more than 80% of the world’s production of leather straps for high-end watchmaking.

The association, based in Neuchâtel, is primarily a centre of competence whose job is to facilitate the traceability and chemical compliance of leather watch straps. While the protection of the environment has become critical, the goals of the AQC also include sustainability of the supply chain. This joint initiative between several competing companies has the merit of going beyond individual interests, as much by necessity as by strategy.

The five founding members represent more than 80% of the world’s production of leather straps for high-end watchmaking.

-

- Angelika Duckenfield, president of the AQC

The initiative is worthy of note, at a time when watch brands are struggling to reach a consensus on how they can unite around a common cause – beginning with climate change.

The association claims to be open, which means that “all stakeholders involved in the leather strap value chain can participate in AQC meetings and work out standards applicable to the profession, in a win-win situation.”

To learn more about this association, we met with Angelika Duckenfield, president of the AQC, Sébastien Bagot, technical and quality manager, and Gwénaëlle Hildebrand, communications manager.

Europa Star: The AQC is a relatively new association, as it was founded in 2014. What is its purpose?

Angelika Duckenfield: It all started with complaints from watch brands: some watches had been confiscated by customs because certain undesirable substances had been found in tests on the chemical composition of the leather straps. At the time, each individual strap manufacturer addressed the complaints, investigated them and found solutions on their own, even though they were dealing with the same problems. The European requirements for the registration, evaluation, authorisation and restriction of chemicals (REACH) have expanded considerably in recent years. Today, more than 220 substances or chemical families are regulated, with a maximum concentration in products. At the time, I was working at the manufacturer Hirsch. Since our supply chain is relatively small in the industry, we came up with the idea of getting together with our competitors to manage this issue on common ground.

“Prior to the AQC, each manufacturer would address complaints, investigate them and find solutions on their own, even though they were dealing with the same issues.”

Has your initiative been well received?

AD: It’s a very competitive environment, with many multi-generational companies. Collaboration was not a given. However, because of the common interest, we managed to get everyone around the table... but at the first meeting, no one dared to speak up for fear of revealing trade secrets! Nevertheless, the complaints continued and the implementation of common solutions simply become imperative. I insisted on this and the AQC was born in June 2014 with five founding members covering 80% of the luxury watch industry’s leather strap supplies. Those who did not join at that stage made the decision mainly for financial reasons, as the association is supported by membership fees.

“At the first meeting, no one dared to speak up for fear of revealing trade secrets! However, it simply became imperative to implement joint solutions.”

What is your role today?

Sébastien Bagot: The two main axes are safety of leather straps and a responsible value chain. That is why our association is a member of the Global Compact of the United Nations, with the aim of implementing the 17 Sustainable Development Goals by 2030. In 2015, we began working on the chemical compliance of leather, and then it quickly expanded to all other components of the leather strap, such as glues, threads and metal parts. We have completed more than 35,000 tests on leather since then.

Another goal of ours is to map the value chain of our member companies. We start from the straps delivered to the watchmakers and go back to the farm. Over the years, transparency has become more and more accepted by the industry.

In addition, sustainability and production efforts made by leather strap manufacturers are independently verified during certification according to AQC standards, which cover social aspects, animal welfare, the environment and traceability systems. The AQC Label guarantees the highest level of quality and safety of the leather strap [see infographic below].

-

- Criteria of the AQC Label

What are your criteria for awarding this label? And how do you navigate the existing certifications?

SB: For chemical compliance, our lists of regulated substances take into account all international regulations applicable to leather straps, and we retain only the most stringent levels. When we started auditing tanneries in 2016, there was no certification that met our requirements. Today, the Leather Working Group (LWG) certification has become the standard. From now on, we will use this certification as a basis for the AQC Label. Our label also recognises other ISO standard certifications. Our policy is to evaluate and recognise certifications that meet the requirements of wristband manufacturers. These requirements are themselves derived from the specifications of the watch manufacturers.

Will LWG certification replace yours in the future?

SB: It is true that for tanneries, our requirements are increasingly converging with those of the LWG. In fact, we are actively involved in the development of their future standard, especially in terms of inbound and outbound traceability. Currently, we still conduct on-site audits of the tanneries supplying our members.

“Our policy is to evaluate and recognise certifications that meet the requirements of the wristband manufacturers.”

How is your skills centre organised?

Gwénaëlle Hildebrand: It employs four people in Neuchâtel. Every month we welcome the managers of our member companies for the steering committee meeting, and every two weeks we organise technical meetings with their experts. Once a year, for our general assembly, we invite the owners of the member companies. In addition, we regularly organise events and working groups so that all actors in the leather strap value chain (farmers, tanners, watchmakers, watch brands, laboratories and umbrella organisations) can exchange sustainability goals, needs and solutions. We do not work in isolation but with the whole industry, as much as we can.

What are the most used leathers for watch straps?

SB: In addition to bovine leathers, alligator accounts for more than 95% of the exotic species used for watch strap leather. For our label, we work with a list of certified and/or audited alligator farms (LVMH, ICFA, Hcp). All these certifications offer guarantees in terms of animal welfare and environmental protection.

What about vegetable alternatives to leather, which even some of your members are starting to develop?

SB: We don’t cover them at the moment, because the definition of what constitutes leather is strict: the skin must be of animal origin.

And metal bracelets?

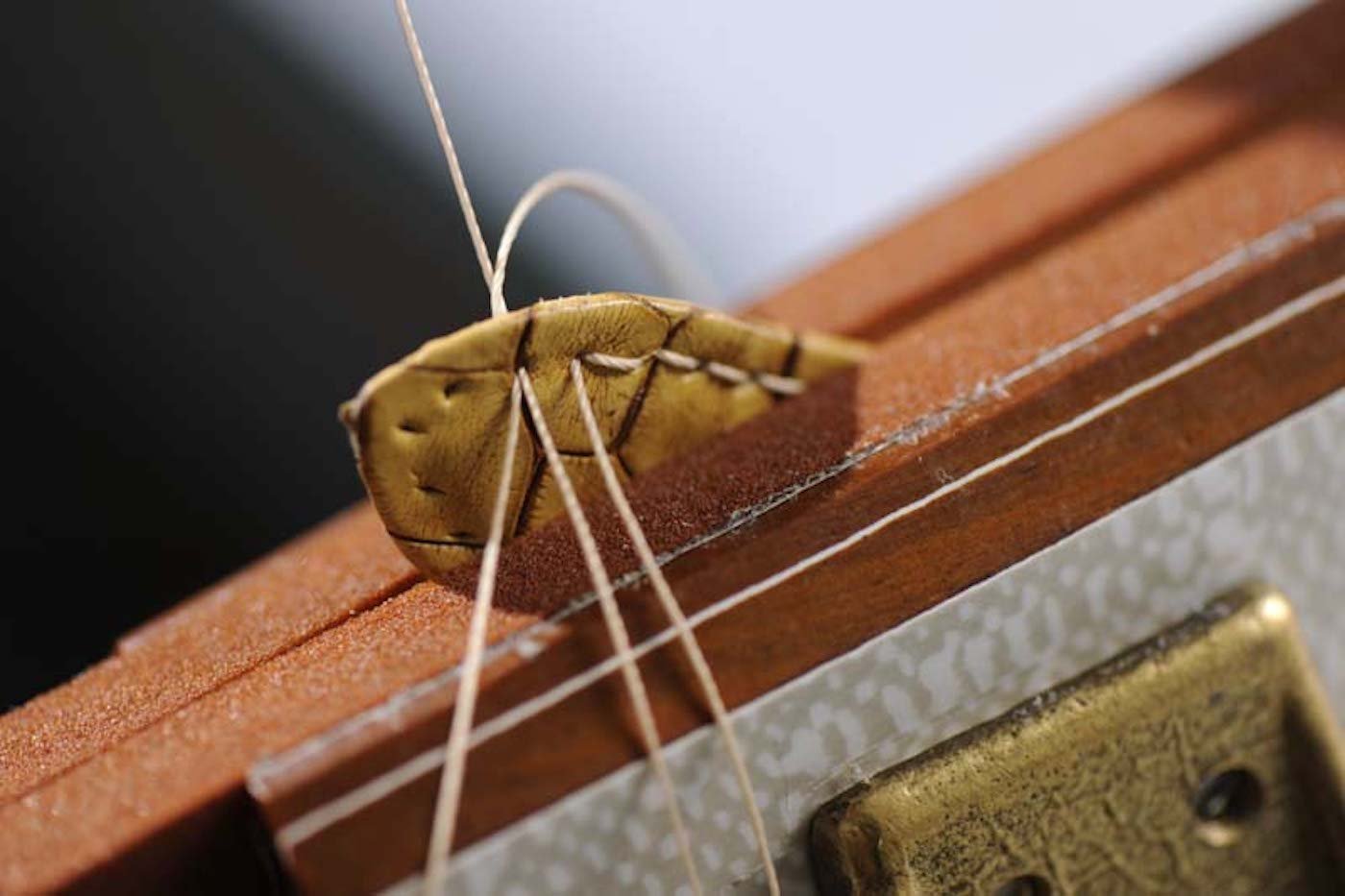

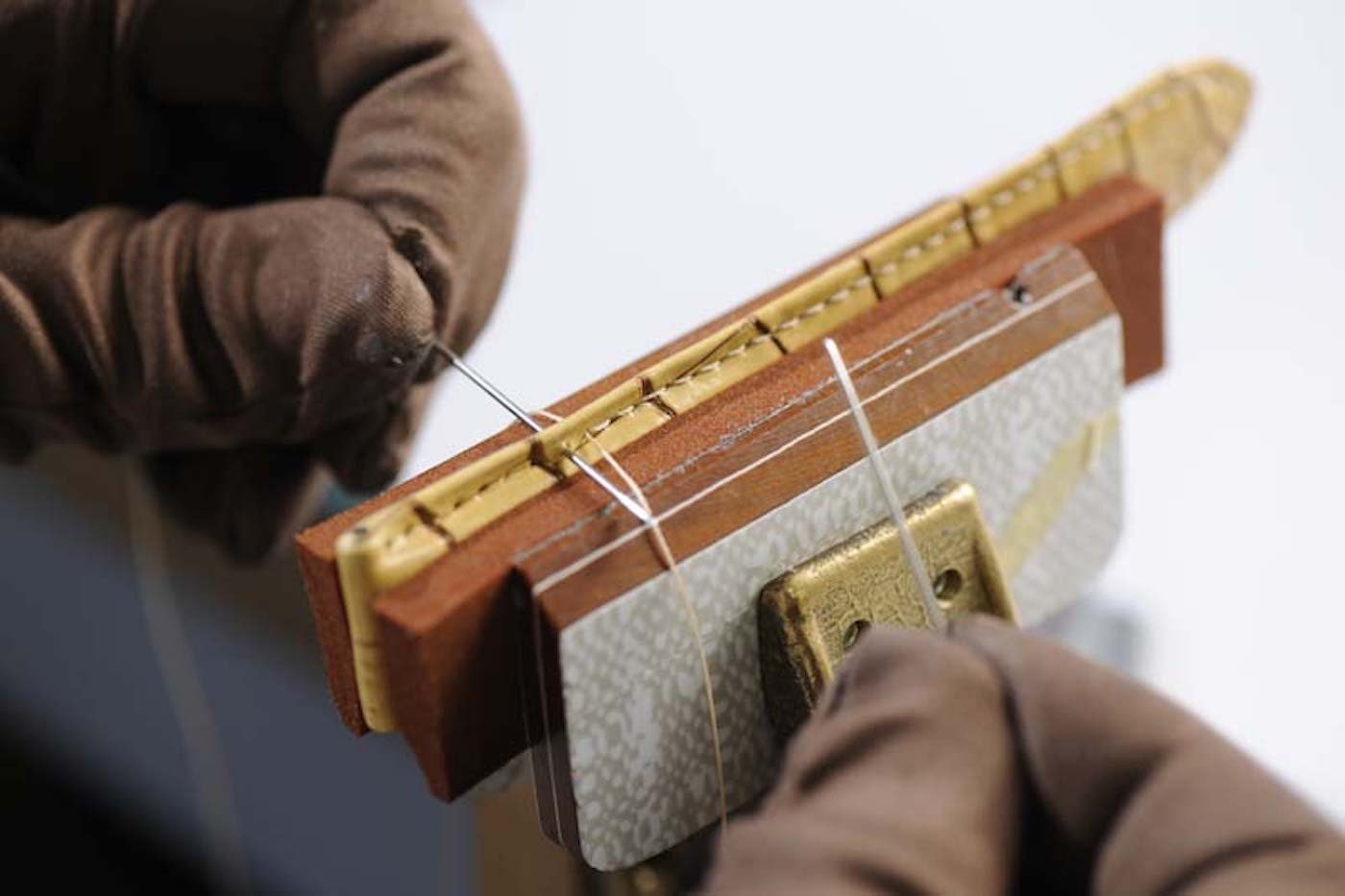

GH: We do not cover those either, as it is a very different business. A minority of our members are also active in metal bracelets, as most are family-owned companies with a long tradition of leather work and handmade goods.

Have the expectations of your members’ end customers – the watch brands – changed?

AD: Watch brands are placing increased demands on their suppliers, as they themselves are making more commitments to sustainable development. Some brands are pioneers and want to set an example, others are taking action but are less communicative. Watchmakers are increasingly including their suppliers in their sustainability strategies.

“Watch brands are placing increased demands on their suppliers, as they themselves make more commitments to sustainability.”

What impact did the pandemic have, on supply chains in particular?

AD: Our members work with high quality leather, in small quantities, so they have been less impacted than players who do volume, such as the footwear industry. In addition, their supply is largely concentrated in Europe for bovine hides and only in the United States for alligator hides. We use products that would be thrown away if we didn’t recycle them, such as the hides of cattle, which are primarily raised for their meat.

That’s not really the case with alligators...

AD: Actually, all parts of the alligator can be used as well! Again, there are misconceptions. In the United States, the ICFA (International Crocodilian Farmers Association) is responsible for the preservation of this species. So much so that there has been an explosion in the number of alligators in the southern United States. The farmers are also responsible for protecting the wetlands, which are a significant source of CO2 capture. In addition, CITES regulates international trade in endangered species.

“Our members’ supply is largely concentrated in Europe for bovine hides and the United States for alligator hides.”

In terms of climate change and the fight to reduce greenhouse gases, what aspects do you take into account?

GH: Our members are committed to measuring their carbon footprint. Each manufacturer is responsible for its own calculation. In addition, the impact of the product itself is assessed: we are currently working on the first carbon-offset watch straps. More broadly, our members are looking for new environmentally friendly design and recycling processes, in a circular economy approach. This involves revisiting traditional methods of manufacturing straps and identifying which materials can be re-used in production. The leather industry has a card to play and we are seeing some interesting experiments. For example, tanneries are starting to use finishing agents based on substances of plant origin. But we still need to evaluate these new options.

If I want to throw away a defective strap, what should I do?

GH: For now, it remains difficult to recycle a strap, as it is made from multiple materials. Studies of biodegradability have been conducted, but to date there is no “compostable” strap, to our knowledge. We are still in the early stages, and we hope there will be solutions in the future. Because the raw material is organic, a leather strap is nevertheless more durable and biodegradable than other types of straps. For example, rubber and synthetic straps, which are very popular today, are made of polymers derived from petroleum. Alternatives to leather use a lot of petroleum-based products.

“For now, it remains diffiult to recycle a strap, because it is made from of multiple materials. However, a leather strap is more sustainable and biodegradable than the alternatives.”

n terms of chemical compliance of straps, what issues are you most concerned about?

SB: The design of the tests remainds a key issue. For example, the majority of leathers are tanned with chromium sulphate, but oxidised chromium can be allergenic. That’s why we introduced a rapid test in 2016, which delivers results in three hours. We are in the process of independently evaluating its performance for a market launch: that way, the test could be used by the entire leather industry, beyond the specific sector of watch straps.

Another problem we had to solve was that different laboratories could produce different results when testing the same product. Since 2015 we have therefore started to carry out inter-laboratory studies, in order to standardise the test results. We are getting very good outcomes on common markers, but this process takes time.

How does Switzerland legislate on leather straps?

SB: Switzerland is adopting the European REACH legislation by ordinance. We try to be involved in future legislation, when consultations are held. This is why we also comment on European regulatory projects in collaboration with the watch brands within the Federation of the Swiss Watch Industry. Our objective is to generate common positions for the entire watch industry.

“We are trying to be drivers of future legislation when consultations are conducted. Our objective is to generate common positions for the entire watch industry.”