ith this new timepiecece, the complex representation of time in flux belonging to Genus finds itself echoed by the moiré, undulating, changing appearance where colour nuances make each piece unique by the very nature of this craft. A fusion of ancestral technique and modern material, an association between creator and wearer – Genus takes an approach to watchmaking that truly defies the conventional.

Thinking differently, combining creativity as well as singularity, leaving the beaten track, inventing instead of replicating, stretching the ingenious whilst ensuring precision, reliability, legibility and wearability: In 2019, Genus opened the first chapter of its story with two remarkable timepieces, the GNS1.2 WG and the GNS1.2 RG. Ten years of research, two inventions and three years of development went into this watch. Two patents lay down the basic principles of the two innovative mechanisms that underpin this free-flowing time display.

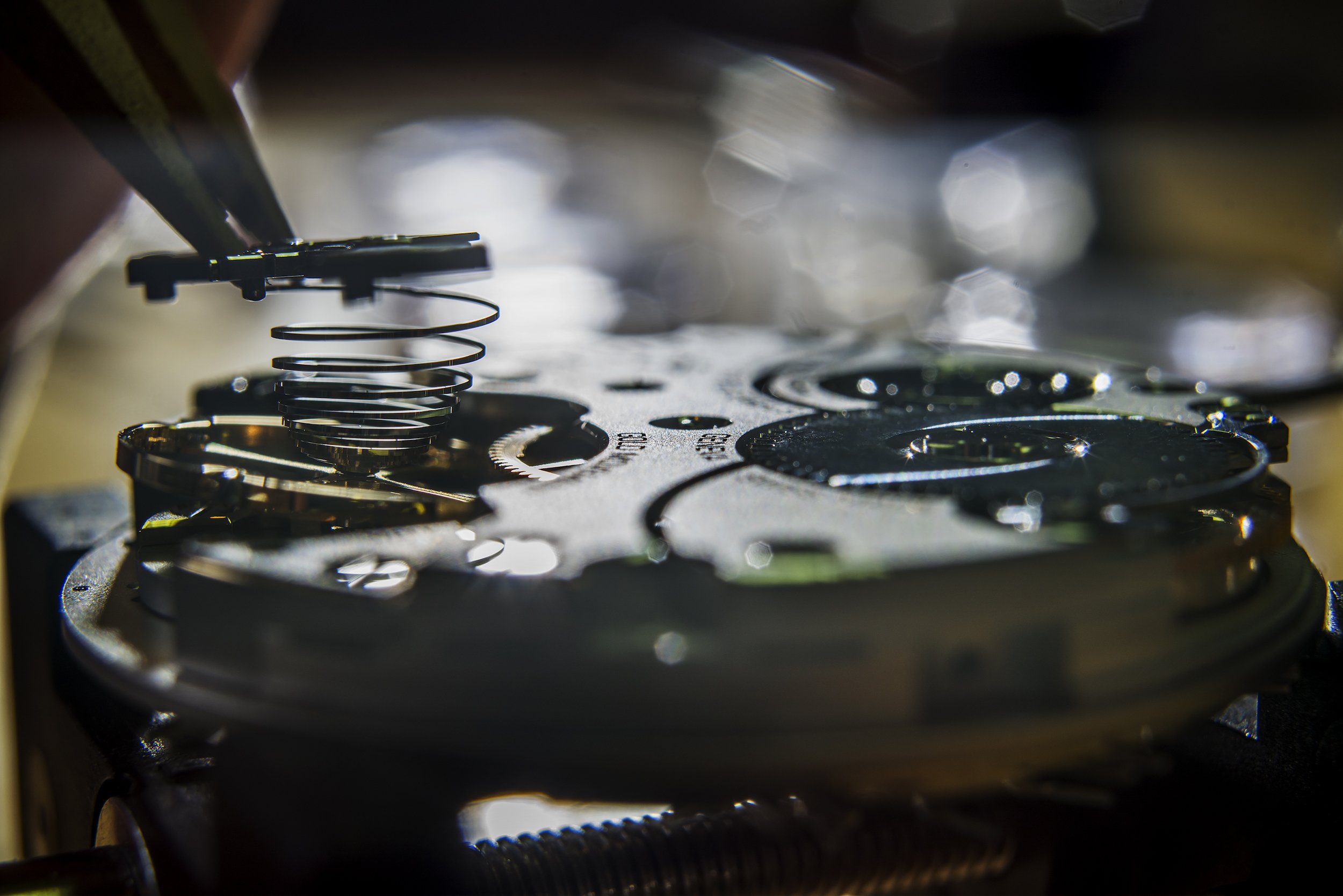

One in rose gold, the other in white gold, both measuring 43 mm in diameter and 13.1 mm thick, featuring the calibre 160W-1.2 or 160R-1.2, a new movement consisting of 418 components, entirely created and manufactured by GENUS in their Geneva workshop. It is a movement characterised first and foremost by its novel complication for indicating time. No dial, no hands. GENUS quite simply invented an unprecedented way of telling time – the mechanism as dramatic performance.

The innovation behind this display complication and its underlying mechanism was imagined, technically, in a completely new and daring way. A new stone humbly brought to the edifice of Swiss horological heritage by the man who invented it, the Master watchmaker Sébastien Billières. An approach first rewarded by the recognition of his peers by the attribution of the prestigious and coveted Mechanical Exception Prize at the Grand Prix d’Horlogerie de Genève (GPHG) in 2019.

Twelve satellites, one for each hour. They make a complete revolution along the periphery of the movement, at the crystal’s edge, once every twelve hours. The fixed white arrow on the left, in front of which the satellites scroll, points to the current hour. To remain in the reading direction, the satellites re-orient themselves and pivot 90 degrees every 3 hours, i.e. four times. The hour numbers – moulded in SuperLuminova™ and affixed to the revolving time-indicating satellites – are the result of meticulous development and design.

Since the launch last year, the months have passed each other at a breath-taking pace, and nothing is the same anymore for the small, independent GENUS team – in much the same way that a Genus watch is unlike any other existing timepiece.

A sentiment rendered even more concrete by the fact that in 2020, GENUS is presenting a new version of the GNS1.2 in a material virtually unheard of in watchmaking: damascene titanium.

It is a new chapter in the Genus story, in more ways than one. The presentation of the new watch is also the occasion for announcing the digital certification of all its timepieces, an effective and modern means of combating counterfeiting and guaranteeing authenticity for the owner of the timepiece throughout its lifetime.

In 2020, Genus re-imagines the GNS by incorporating it in a new metal case. After white gold and rose gold, the brand ventures into new territory for watchmaking with a damascened titanium case, hence the name GNS1.2 TD (Titane Damassé). Applying the Damascus smithing technique to titanium requires a rare savoir-faire. In fact, the skill is listed in the Inventory of Intangible Cultural Heritage in France. It is craftsmanship elevated to art, true artisanship, the domain of only the best metalsmiths. In Japan it is called Mokume-gane, where it has been used to forge katana sword blades since the early 17th century.

The art of damascening consists of forging sheets of metal layer by layer. After having been hammered, each sheet is folded back upon itself, and the operation is repeated as many times as necessary – one might say like preparing the laminated dough used for puff pastry. This homogeneous ‘stacking’ of homogeneous layers, each one annealed between each fold, gives the material an entirely new, very particular aspect. Each incision, each bevel into the edge of the damascened metal reveals the strata, the shapes, the undulations, the unique character of each layer.

The difficult work, at the heart of the forge’s embers, of folding and layering is usually done with iron or steel for katana blades. Although 40% lighter, titanium is three times harder and can be forged at temperatures 300 degrees higher than for conventional watchmaking steel. This makes the method, which remains largely manual, quite laborious, and complex. In addition, to further enrich the appearance of this basic material, Genus works with layers of various titanium alloys, each of which exhibits a different tint and reaction to heat. The colourful effect is rendered even more visually arresting by the final heat treatment that determines the general tone of the metal block, along with its subtle differences in tints and hues.

Each part of the GNS1.2 TD’s casing is cut at an angle to achieve a different, unique appearance. Genus then works to coordinate the different parts that make up a watch. Here, the intimate relationship between GENUS and the wearer again comes into play. Indeed, the future owner is invited to attend the ‘damascene revelation’ by open flame at the Genus workshop in Geneva and will be able to intervene directly in the colouring as well as decide on a particular surface finish: matte, satin or polished. Only the owner shall be privy to the secrets of the manufacturing process and the artisans’ skills.

At the core of the GNS1.2 TD, the same heart, the same brain as in theGNS1.2 WG – the 18K gold in-house calibre that was awarded the Mechanical Exception Prize at the Grand Prix d’Horlogerie de Genève (GPHG) in 2019.

Creativity, innovation, singularity being the intrinsic values of Genus, the calibre 160W-1.2 forms the natural foundation of this authentic, genuine, and sincere watchmaking approach.

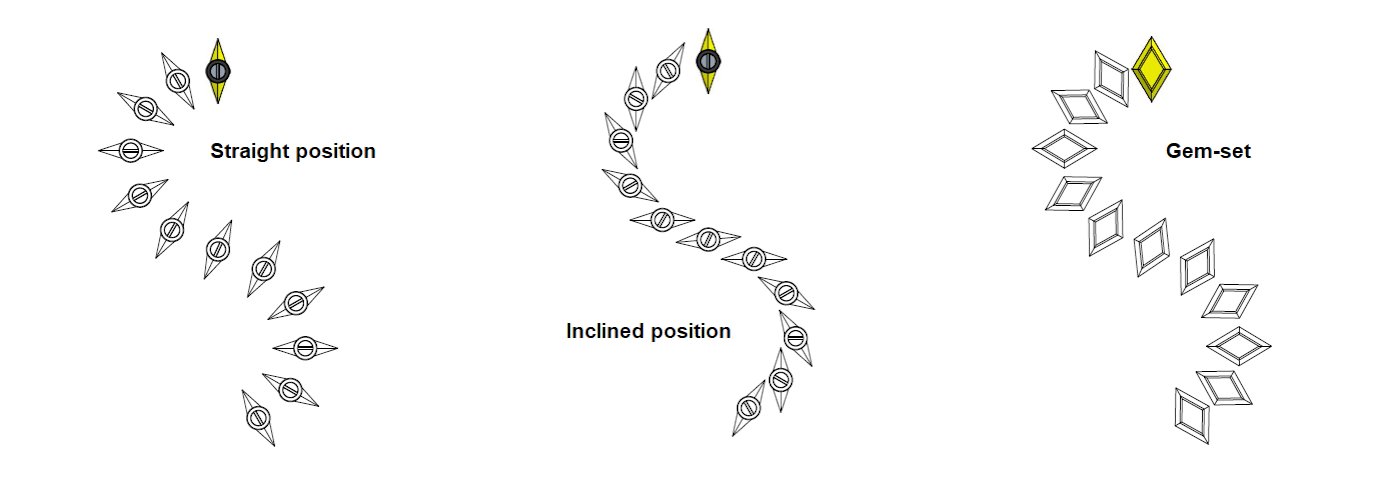

Particularly attentive to its customers, and always receptive to their wishes and preferences, Genus has made several adjustments to its masterpiece. For instance, the orientation of the ‘genera’ – the hallmark free-moving elements that flow in a pattern to indicate the tens-of-minutes – can now be personalised. They can be set straight or inclined, depending on the wearer’s aesthetic preference for the watch. This option can provide a more comfortable legibility for some owners.

In addition, Genus adjusted the curvature of the sapphire crystal which eliminated the perceived ridges on the upper perimeter. This mitigates any visual distortion of the hour indices, thereby improving clarity of the timekeeping mechanism.

The architecture of the movement is indicative of the genetics of the Genus project. The intrinsic principles of freedom, flexibility and future evolution are based on its separation in two parts. The base, which can be described as the foundation of the movement, groups the essential functions, including a single barrel. It ensures a 50-hour power reserve, which is considerable in view of the complexity of the calibre and the moving elements. On top of this are built the individual complication modules for managing the display of hours, and tens, and units of minutes.

All the components of the calibre 160W-1.2 have been designed and hand-worked by the watchmaker in accordance with the requirements and tenants of Haute Horlogerie. The main plate and bridges are made of 18K gold obtained through an ecologically and socially responsible supply chain, certified by the RJC (Responsible Jewellery Council). Another advantage: Gold has an anti-magnetic property and is therefore largely protected from the harmful influence of magnetic fields. Finally, gold lends itself extremely well to the finest finishing techniques.

The surface finishing treatments of the 418 components of the calibre 160W-1.2 are at the heart of Genus’ approach to watchmaking. Each and every tiny part has been worked and re-worked with the most meticulous care and in strict compliance with the requirements and standards of Haute Horlogerie. The escapement bridge is mirror-polished, as are the two beautiful arrow indicators that show the hours (at 9 o’clock) and minute units (at 3 o’clock), to name just a few of the many other components finished in this manner. The plate and the three bridges are micro-beaded, creating a matte effect that allows the glossy finishes to stand out against a contrasting background. All their edges have been bevelled and polished. The visually arresting effect is further enhanced by their shape with curves that vibrantly reflect any play of light.

Behind the signature time display of Genus is a succession of challenges that took ten years of gestation and three years of development. The two main inventions that distinguish the GNS timekeeping mechanism have patents pending: the rotating and peripheral display of the hour satellites, and the passage of the ‘genera’ from one analemma orbit to the other.

Coupling the ‘genera’ to the foci counter-rotating minute wheels was a major test. On the one hand, the ‘genera’ must be held in place; on the other, they must be able to move freely from one minute wheel orbit to the other, flowing in the figure eight of an analemma. An undertaking made all the more challenging by the fact that the changeover between the upper and lower orbits must take place with twelve ‘genera’ in a row, all without damaging or wearing the blued finishes of the minute wheels.

Consider the toothed wheel guiding the hour markers - one of the largest there is - with its teeth located on its inner edge. This large wheel must be perfectly flat – even after it has been precisely cut by electro-erosion wire, and hand-finished. Finally, an unrelenting, meticulous focus on reducing friction to a minimum to maximise power generation and energy distribution is undertaken to ensure running time that is compatible with current standards whilst feeding a complex mechanical timekeeping system.

Clients accustomed to fine conceptual watches, who may have been scalded by past projects, probe the reliability of their movements with assiduousness. The integrity of Genus, of its founders, is the best guarantee of its merit. Their combined experience as visionaries and entrepreneurs, creators and perfectionist risk-takers has established at the very heart of GENUS’ watchmaking culture, an innate drive to produce innovative watches that are different and reliable for many years to come.

To offer owners the Genus guarantee of their timepiece’s authenticity and traceability throughout its life, Genus has joined forces with the Arianee Project. It is an independent consortium whose mission is to establish a global standard for the digital certification of valuables. Based on blockchain technology, the decentralised and open source protocol offers a set of new services for the watch owner, which are directly accessible from the Certificate of Authenticity delivered with each Genus watch.

The specifics of each timepiece, and in particular for bespoke orders, the sale and/or transmission to a new owner, the service book, proof of ownership/declaration of theft – the Arianee protocol allows Genus not only to free itself from paper-based authentication (which can be counterfeited) of its timepieces, but above all guarantees its customers a traceability of their watch throughout their life, even if the ownership changes over time.

Thus, Genus timepieces benefit from a unique and forgery-proof digital identity, a ‘Digital Passport’ if you will, accompanied by a photo of the acquired timepiece with its individual serial numbers (not just a catalogue photo), which opens up a new channel of communication – permanent, secure and anonymous – between the brand and the owner of the timepiece.