ith the RM 16-02 Automatic Extraflat, Richard Mille reveals a new artistic vision for the collection’s original rectangular timepiece, the RM 016. This latest model daringly reinterprets the brand’s established aesthetic codes. Resolutely contemporary in style, the RM 16-02 boasts a sobriety of line that conceals a wealth of technical sophistication.

At first sight, the watch stands out for its unique urban aesthetic, fully owning its unconventional approach to watch conception. Showcasing the authenticity of its materials and the refinement of a design stripped of artifice, its strong character draws on the example of Brutalist architecture. Interlaced forms suggest a fascinating maze drawing in the eye, where each detail revealed is an invitation to further exploration. Like the passages of a labyrinth, the design plays on optical illusions, conjuring the allegory of a single, structured path, where aimless wandering yields to contemplation.

Mechanics-wise, Richard Mille’s expertise takes pride of place. The Calibre CRMA9, the 15th and latest addition to the in-house family of movements, is an engine specially imagined for the RM 16-02. The Brand’s movement engineers designed this tangle of titanium to maximise the entrance of light thanks to the cutaways of its openworked elements.

Purity of line and efficiency of every component are the watchwords governing this movement. The skeletonised baseplate in microblasted grade 5 titanium with a grey electroplasma coating covers the entire visible surface of the watch. Only the minutes bridge stands out, distinguished by its black PVD coating. The extreme skeletonisation of the CRMA9 Calibre is impressive, calling as it does for infinite precision in the milling and finishing of its 67 openings of varying sizes, with chamfered edges finishing each cut. Almost 2 hours of milling per plate and dozens of separate manual operations are necessary to complete this meticulous process.

Time well spent, as the skilfully orchestrated openings create an impression of lightness and transparency, while accentuating the interplay of shapes and depth within the movement. A genuine triumph of engineering, the baseplate further enhances the modern feel of the timepiece while simultaneously revealing the technical complexity at the heart of the creation. The bridges on the back lend its silhouette a rich complexity. Like the baseplate, these parts have undergone rigorous 10-year aging and shock-resistance tests to ensure they withstand the rigours of everyday life.

Against the background of the movement, whose full volume is accessible to the eye, emerges the entirely new silhouette for the oscillating weight, fashioned in platinum and fitted with two grade 5 titanium inertia blocks. The bidirectional rotor is mounted on ceramic ball bearings for efficient winding of the 50-hour power reserve.

One visual signature of this timepiece is visible on the dial, namely the hour markers. These are based around a thread-like decal that appears as it runs through the skeletonised maze of the movement, bringing the hours to life. The carefully designed indices play with perceptions, sketching an enigmatic motif inviting the observer to decipher them to establish a subtle relationship between watch and wearer.

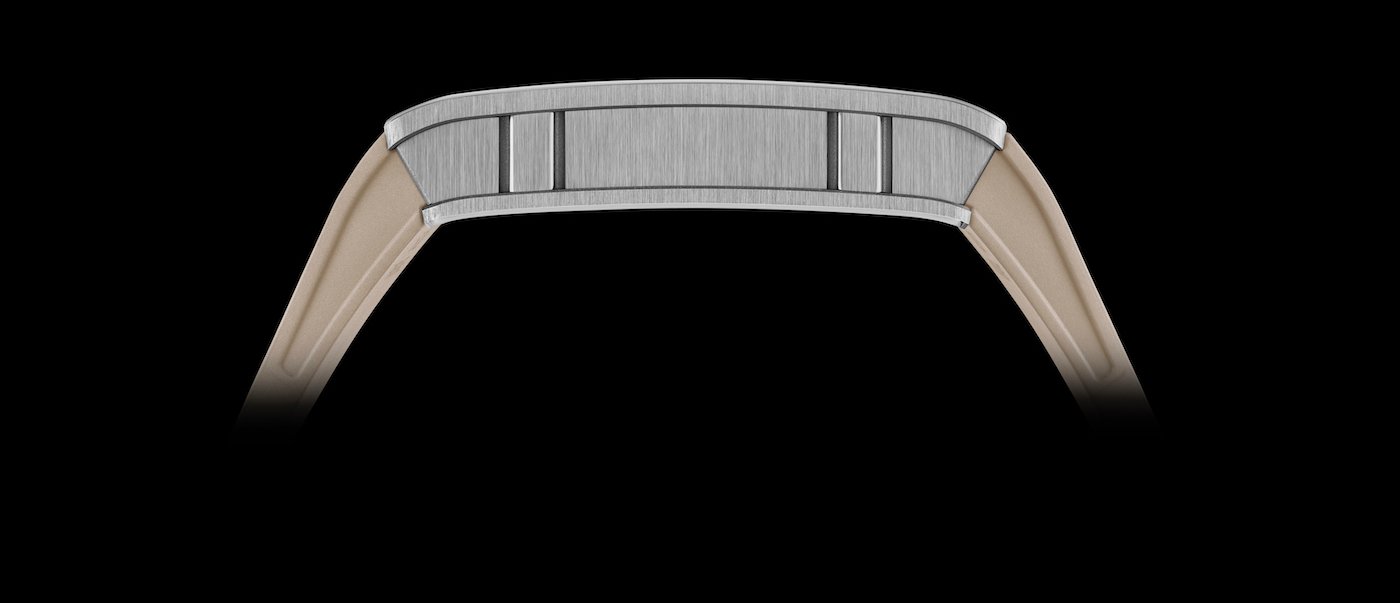

Above and beyond its technicity, the attractions of the RM 16-02 include its sculptural rectangular shape and 30-metre water resistance. The extra-flat case stands out for its ergonomics, which have been subtly optimised compared to the original RM 016.

At 36 x 45.65 mm, it is 10% smaller than its predecessor, perfectly espousing the wrist while enhancing the brand’s characteristic lines.

Two interpretations are available for the case of this watch. One is clad in full grade 5 titanium with microblasted, satin finishing and polished bevels. The other sports Terracotta Quartz TPT®, and entirely new colourway. This singular shade is the result of an innovative process: silica threads just 45 microns in diameter are impregnated with a coloured matrix, then stacked with a 45° angled between layers and heated to 120°C at 6 bars of pressure. The raw composite milled for the case is set atop a caseband made of Creamy White Quartz TPT®. The result fully embodies the original intention of designing an object devoid of affectation, a philosophy that pervades Brutalist architecture.

The RM 16-02 Automatic Extraflat evokes aesthetic inventiveness as well as mechanical discipline, with a resonance that invites the imagination in both dynamic and meditative directions.

TECHNICAL SPECIFICATIONS

Skeletonised automatic winding movement with hours and minutes.

DIMENSIONS 26.00 x 31.25 x 4.12 mm JEWELS 25 BARREL ARBOR AP 20 steel BALANCE CuBe, 4 arms, 4 setting weights, moment of inertia 7.5 mg•cm2, angle of lift 50° FREQUENCY 28,800 vph (4 Hz) BALANCE SPRING AK3 SHOCK PROTECTION Incabloc 908.22.211.100 (transparent) POWER RESERVE Around 50 hours (10%).

BASEPLATE AND BRIDGES IN GRADE 5 TITANIUM

Grade 5 titanium with electroplasma treatment lends great rigidity to the baseplate, as well as the precise surface flatness essential to perfect functioning of the gear train. The bridges are also made of grade 5 titanium, with a grey and black PVD treatment. These components are satin-finished, microblasted and beveled by hand.

The skeletonised baseplate and the bridges were subjected to separate and extensive validation tests to ensure they met rigorous strength requirements.

FREE-SPRUNG BALANCE WITH VARIABLE INERTIA

This type of balance wheel represents the ultimate in innovation. It guarantees greater reliability when subjected to shocks and during movement assembly or disassembly, hence better chronometric results over time.

The regulator index is eliminated, and a more accurate and repeatable calibration is possible thanks to 4 adjustable, small weights located directly on the balance.

PLATINUM ROTOR

By using a platinum rotor with titanium weight segments in combination with a One Way® reverser system mounted on ceramic ball bearings, the barrel can be optimally wound.

FAST-ROTATING BARREL (5 HOURS PER REVOLUTION INSTEAD OF 7.5 HOURS)

This type of barrel provides the following advantages:

• The phenomenon of periodic internal mainspring adhesion is significantly diminished, thereby increasing performance.

• Provision of an excellent mainspring delta curve with an ideal power reserve/performance and regularity ratio.

GEAR TEETH PROFILE

The entire going train of the watch, the primary transmitter of power throughout the movement, utilises a special profile for the wheel teeth. Developed specifically for the Calibre CRMA9, these wheels ensure a 20° pressure angle. This system equalises any discrepancies that might arise between the centres of each wheel, for instance due to thermal changes and normal use, and promotes the smooth transmission of torque to the balance wheel, thus supporting excellent chronometric results.

SPLINE SCREWS IN GRADE 5 TITANIUM FOR THE BRIDGES AND CASE

This permits better control of the torque applied to screws during assembly. These screws are therefore unaffected by physical manipulation during assembly or disassembly and age well.

FINISHING

MOVEMENT

• Hand-polished anglage

• Microblasted milled section

• Microblasted sinks

• Electroplasma treatment on the baseplate

• Electroplasma and black PVD treatments on the bridges

STEEL PARTS

• Satin-finished surfaces

• Hand-polished anglage

• Hand-polished bevelling

• Hand-polished locking section

WHEELS

• Concave chamfering with a diamond tool

• Diamond-polished angles

• Circular-finished faces

• Rhodium plating (before cutting the teeth)

• Minimal corrections applied to the wheels in order to preserve geometry and performance

CASE DIMENSIONS

36.00 x 9.50 x 45.64 mm

UPPER FLANGE

Carbon fibre; hour index points filled with approved luminous material.

DIAL

Sapphire. Thickness: 0.40 mm

CRYSTAL

Bezel side

• Sapphire (1,800 Vickers) with anti-glare treatment (both sides)

• Thickness: 1.35 mm

Case back

• Sapphire with anti-glare treatment (both sides)

• Thickness: 1.40 mm at the centre